Choosing the Right Burs for Optimal Restorative Results and Productivity

The positive impact on restorative excellence and productivity of selecting a premium diamond or carbide bur is often overlooked. Procedural efficiency is not limited to using the fewest number of burs to achieve the desired clinical result. In addition to the number of burs in the preparation sequence, the shape, diameter and coarseness of each individual bur has a significant effect on the efficiency as well as quality of the clinical result. Often underestimated as a factor influencing the final restorative outcome is the quality of the bur itself. The manufacturing quality of a diamond and carbide bur can have a profound effect on the final restoration as well as the health of the tooth and handpiece. One of the choices a clinician has to consider is the significant differences between a premium bur and a seemingly low-cost bur. This is an area where initial cost savings may result in more overall procedure time and a less predictable restorative outcome.

"Low-cost burs will become dull more quickly, requiring more pressure on the tooth surface to sustain performance."

Due to stricter quality control during manufacturing, a premium bur will produce a higher cutting efficiency creating a preparation that is faster, smoother, and more precise. In general, low-cost burs will become dull more quickly, requiring more pressure on the tooth surface to sustain performance. This can cause an increase in tooth surface temperature and stress on the handpiece. In the case of a premium diamond bur, the quality manufacturing process ensures that the bur rotates in balance and the diamond particles are evenly distributed and won’t separate from the shank pre-maturely, an event that can reduce cutting efficiency and accuracy as well as increasing bur vibration. A bur that rotates in balance or “true” will rotate with far less vibration and will be kinder to both the tooth and handpiece. Reducing iatrogenic trauma to the tooth is key, but longer periods of time between repairs and increased longevity of the handpiece is also a benefit of choosing a premium bur.

Komet® diamond and carbide burs have been manufactured in Germany for 100 years by the Brasseler family. Komet's line of premium rotary instruments covers the spectrum of restorative preparation and finishing and the brand is known for its pairing of science with strict adherence to manufacturing excellence. Komet's quality assurance goes beyond their line-up of multi-use diamond and carbide burs as the company also offers premium single-use, sterile burs for the clinicians that prefer this concept of bur utilization (available in Canada since the end of 2022).

A bur that rotates in balance or “true” will rotate with far less vibration will be kinder to both the tooth and handpiece

Seeking restorative excellence is always the goal. Improving clinical efficiency means selecting those products and instruments that reduce procedural chair-time while maintaining or improving restorative excellence. Choosing Komet diamond and carbide burs as part of the restorative armamentarium can greatly improve clinical efficiency through faster, more accurate preparations and finishing techniques while ensuring more predictable, high quality clinical outcomes.

Start with these true and trusted Komet best-sellers:

Crown Preparation

Margin Refinement

8856 Tapered Chamfer Diamond margin refinement bur, fine grit 8856.FG.016 (190053)

8856 in use

Cavity Preparation

The opening of the cavity and the initial preparation are noticeably simplified with the help of these structured diamond instruments. The use of S-Diamonds is highly recommended for increased efficiency. Their particular advantages make structured diamond instruments especially suitable for a gentle treatment.

S-Diamonds® Advantages:

- The combination of a structured blank and coarse grit allows quick and effective substance removal and improved cooling

- The faceted structure of the blank reduces clogging and consequently the generation of heat

- The operation becomes notably more effective

- The time saved during treatment is equally beneficial to you and your patient

Structured blank

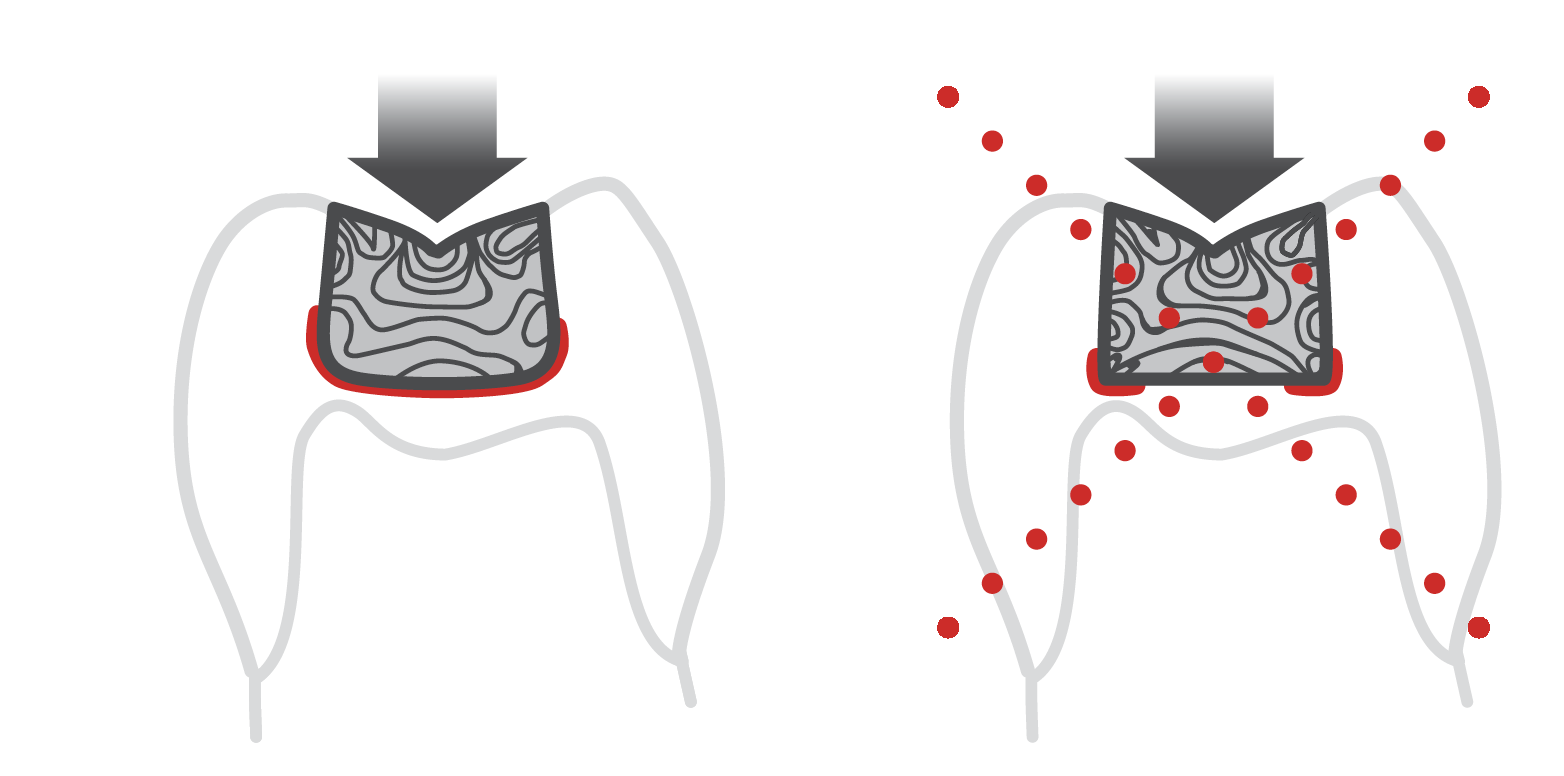

In order to prevent the formation of micro cracks, it is recommended to use instruments with rounded tip profiles.

The red marking illustrates the different distribution of forces.

In order to prevent the formation of micro cracks, it is recommended to use instruments with rounded tip profiles.

The red marking illustrates the different distribution of forces.

Removal of Amalgam Fillings

H32 Tungsten Carbide Amalgam Removal Bur H32.FG.012 (338051)

For a remarkably quick removal of amalgam fillings without adverse health effects.

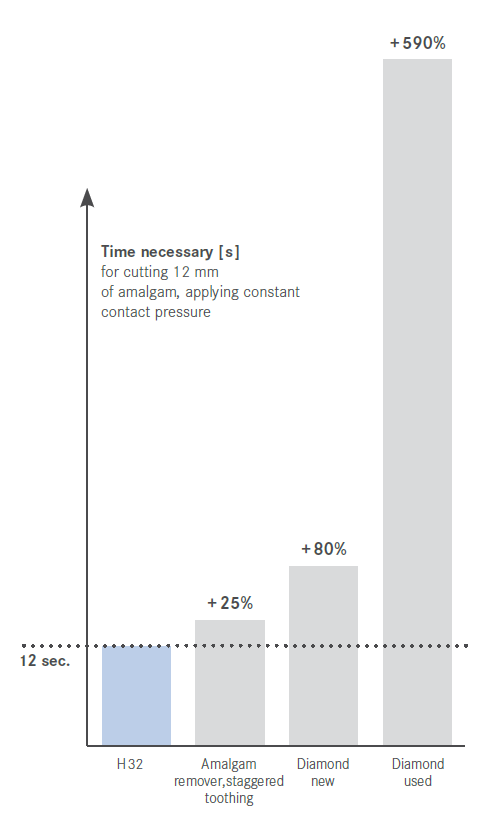

The removal of old amalgam fillings has always been a topic of discussion in the dental practice. Besides the aspects of health protection, special emphasis has been placed above all on keeping the treatment time as short as possible. The H32 has been developed as a specialized instrument for this very purpose.

- Amalgam remover with innovative toothing and blade configuration

- Superior performance due to shorter treatment times

- Transverse tip for easy penetration into the restoration

Performance chart: Komet H32 Amalgam Remover vs. other amalgam removing burs.

Discover More

This article was originally published in the Clinical Life™ magazine: Spring 2022 edition